About Polyurethane

The formation process of the polyurethane industry started in 1849 with the discovery of a reaction involving isocyanate and hydroxyl compound by Wurtz and Hoffman and the discovery of urethane, and then entered our daily lives in 1937 when Dr. Otto Bayer adapted this reaction to a commercial use.

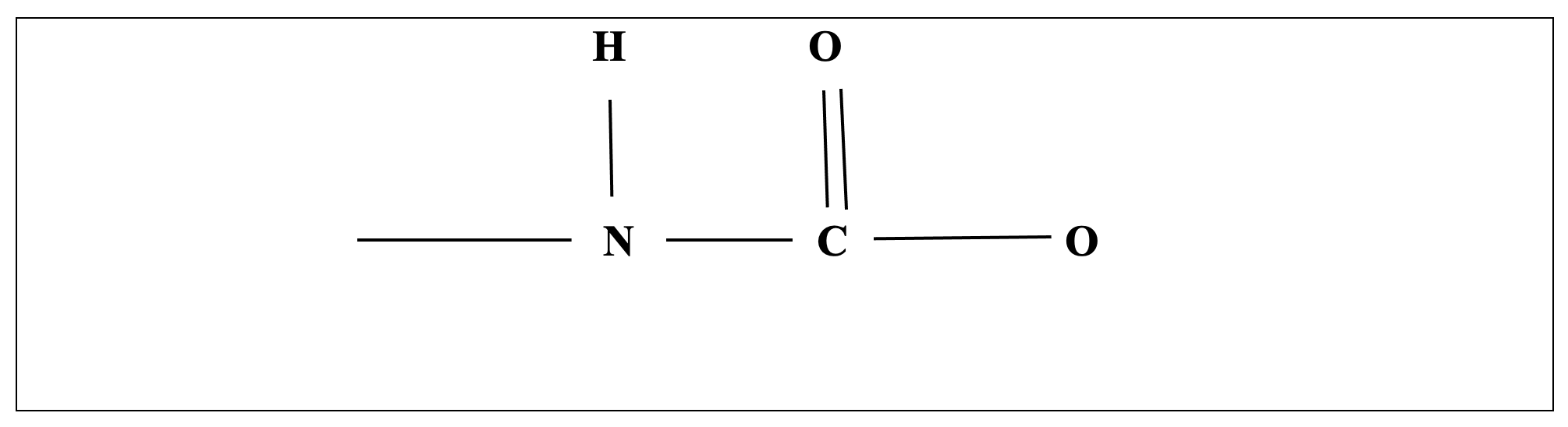

The term POLYURETHANE means polyfunctional isocyanates that form plastic (polymer) as a result of addition reaction with compounds containing at least two hydroxyl groups. Polyurethane (PU) takes its name from the name URETAN formed as a result of this reaction. Materials in this class may also contain urea, amide, ether, ester bonds. Therefore, the name polyurethane is used for polymers with a very variable structure.

During the chemical process, the polymers bond with the urethane group to form a versatile solution that can take many forms. Thanks to this very special chemical structure of polyurethanes, safe, durable, useful, modern and environmentally friendly products have been obtained and the daily lives of millions of people have become easier. Playing an important role in making our lives more convenient, comfortable and environmentally friendly, this material is used in a wide variety of applications to create all kinds of consumer and industrial products.

PU SYSTEMS

The formulation of different Polyurethane starting materials for specific applications to meet customer needs is called PU System and is usually 2-component.

Component A consists of a polyol blend, catalysis and other additives and component B consists of a prepolymer containing isocyanate or an NCO.

WHERE ARE THEY USED?

Polyurethanes are used in a wide variety of applications thanks to their various physical and chemical properties, their ability to replace materials with limited use and their ability to be found in different forms. Polyurethanes, which are a versatile material with their elasticity, durability, hardness, robustness and safety, are present in almost everything we touch in our daily lives, even if they do not directly catch our eye. It is possible to find polyurethane in the chair we sit in, the car we drive, the bed we sleep in, the shoes we wear and countless other items we use. Many industries utilize polyurethanes in their products.

Polyurethanes are used in a wide variety of applications due to their various physical and chemical properties. The first application area that comes to mind is foam products.

Flexible Soft Foam: Polyurethane's flexible low-density soft foam is used to make many different products such as mattresses, furniture upholstery, automobile seats, pillows and insulation material. This type of polyurethane provides comfortable and durable fillings.

Rigid Foam: Rigid polyurethane foams are used in a range of industrial applications such as insulation, packaging materials and lightweight structures. They offer a highly effective and lightweight material for thermal insulation.

Foam Gaskets: Polyurethane foam is used to make gaskets that provide water and air tightness.

Elastomers: Polyurethane elastomers are used to provide flexibility and durability in products such as wheels, bearings, gasket materials, shoe soles, automobile shock absorbers and sports equipment.

Coating Materials: Polyurethane coating materials are used to protect and give an aesthetic appearance to wood, metal, plastic and concrete surfaces. They are seen in many different applications such as furniture polish, floor coverings and automobile paints.

Adhesives and Sealants: Polyurethanes are used as components of structural adhesives and sealants.

Technical Parts: Polyurethanes are used to make engineering parts due to their durability and chemical resistance.

GENERAL PROPERTIES

The main characteristics of polyurethanes that play a role in their choice;

Board MemberVersatility of the material

When we look at what makes polyurethane so important, we can see that it has countless applications due to its versatility. The large number of raw materials with very different properties required for polyurethane synthesis makes polyurethanes a very important and interesting material. The properties of polyurethanes are highly dependent on the manner in which they are produced. For example, if the polyol chain used as a raw material in the preparation of polyurethane is long and flexible, making the final product soft and elastic. On the other hand, if the extend of crosslinking is too high, the final polyurethane product will be tough and rigid. This versatility makes polyurethanes ideal for use in many different applications, from automotive components to medical equipment. The unique properties of polyurethanes make them ideal for a wide range of applications, from insulation to furniture.

Board MemberHardness & Robustness

Polyurethane is an extremely hard material with exceptional tear resistance. Thanks to this feature, it will last longer than many materials in highly corrosive environments.

Board MemberFlexibility & Lightness

It can be molded in various shapes and sizes. This flexibility creates unique and innovative designs in the furniture and footwear industry, as well as creating an extraordinary comfort zone in our lives.

Board MemberChemical resistance and durability

Polyurethane coatings are ideal for use in industries such as automotive as they are resistant to abrasion, tearing and impact. In addition to their mechanical properties, polyurethanes offer exceptional chemical resistance. This makes them ideal for use in the chemical industry where they can be exposed to harsh chemicals.

Board MemberInsulation Property

Thanks to a uniform foam structure, heat retention is excellent. Thanks to its closed cell structure, it also provides sound insulation. Thanks to this excellent insulation feature, high energy savings are achieved.

Board MemberAdhesion Property

Since they have good adhesion, they can adhere to almost any applied surface.

Board MemberLow Cost and Easy Processability

Thanks to their low cost and easy processability, they have become the first choice of most manufacturers.

Board MemberFire prevention

Thanks to its airtight feature, it has the ability to prevent both fire progression and smoke.

Board MemberRecyclable

It can be reused chemically when broken down into its chemical components, mechanically when reused in polymer form, and even as a raw material for new polyureas.

Board MemberEnvironmentally friendly

Polyurethanes do not produce bacteria and are environmentally friendly due to their hygienic and recyclable properties. By reducing the need for energy, it allows us to protect the limited natural resources of our world.

The importance of polyurethanes in our daily lives is constantly increasing as their usage areas increase.

In short, it is very difficult to imagine a world without them.

ADVANTAGES

Polyurethanes have endless formulation possibilities. Its high flexibility, adjustable hardness range, unique abrasion resistance, resistance to UV radiation, easy processability and even adaptability to meet special needs such as color make it a very advantageous material compared to many other materials.

Its most important advantages are that it is affordable and safe, it is sustainable, it reduces the need for energy and protects our environment and natural resources, it makes our lives comfortable in many areas, it is recyclable, it does not deteriorate in intensive use, the total weight of the finished product decreases in proportion to its increasing use in wood, metal and ceramic products and therefore the transportation cost decreases.

The polyurethane industry is constantly evolving and new formulations are being developed on a regular basis. Some of the latest developments in formulations include bio-based polyols produced from renewable resources and high-performance polyurethanes that offer exceptional resistance to heat and chemical exposure.

SECTORS

Today, the sectors where polyurethane is most widely used can be grouped under the following headings;

Heating and Cooling Sector

Polyurethane rigid foam is the most widely used thermal insulation material for refrigerators, freezers and cold storage. Similarly, it is used for thermal insulation in boilers and solar energy panels in the heating sector. Thanks to this feature, it reduces the energy consumed by maintaining the desired temperature.

Footwear Industry

Polyurethanes are used in the footwear industry in a wide variety of shoe models. Comfortable, lightweight and abrasion resistant polyurethanes are very suitable for shoe soles. Lightweight polyurethane soles also prolong the sweating time.

Polyurethane shoe soles provide a comfortable use thanks to its soft sole, while the perforated structure resembling a sponge in its internal structure allows the shoe to breathe, prevents odor formation and provides a healthy use.

Building/Construction and Insulation Sector

Polyurethane foams, one of the most widely used materials in the building sector, are especially preferred for insulation. They are used for filling gaps, thermal insulation, water and sound insulation. They are used as coating, protection and filling materials to meet the needs in different areas. Polyurethane-based materials are durable, long-lasting and high-performance products. They provide high thermal insulation on roofs, walls, windows and floors. They are also used as coating materials in interior and exterior spaces.

Automotive Sector

It is preferred in the automotive industry due to its durability, lightness, heat and conductivity insulation, resistance to corrosion, ease of design and production, and comfortable and safe driving characteristics. With its lightweight feature in vehicles, it is aimed to use less energy and less emission formation. It is applied in many parts such as seats, backrests, headrests, sun shades, steering wheels, instrument panels, sound insulation, gear knobs, hard bumper foams, roof coverings, armrests, air filters, etc. Since polyurethanes are very strong and light at the same time, they reduce the total weight of automobiles and thus provide fuel efficiency and environmental performance.

Furniture and Sponge Industry

Flexible polyurethane foam is used as a cushioning material for upholstered furniture. It makes furniture more durable, comfortable and keeps its shape. Elastic polyurethane foam is used in the production of upholstery foam and mattresses, viscoelastic pillows. It also creates solutions that provide decorative advantages in the furniture industry.

Other Uses of Polyurethane

Polyurethane elastomers are used in a wide range of applications, particularly in engineering where durability, abrasion resistance and chemical and oil resistance properties are required. Applications include rollers and belts to transport minerals in quarrying, wheels for roller skates and hospital trolleys, rollers for printing processes and hoses, and other components in under-the-hood automotive applications. Apart from sealant applications in construction and automotive, sealants are also used in electrical and electronic equipment to prevent moisture from entering components such as connections and switchgear devices.